We're fascinated with the possibilities implicated by the rapid development of faster, cheaper,

We're fascinated with the possibilities implicated by the rapid development of faster, cheaper,

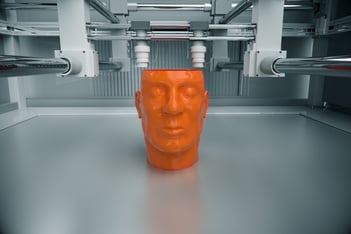

more efficient 3D printers. 3D printing had its advent in 1983, with a printer invented by Chuck Hull called a stereolithographer (SL or SLA), that used UV-curable liquids as its media.

3D printing, also known as additive manufacturing (AM), according to Wikipedia, refers to "processes used to synthesize a three-dimensional object, in which successive layers of material are formed under computer control to create an object."

Simply put, 3D printing starts with a digital design, which is then realized by the printer by adding layers of material, resulting in a three-dimensional physical object.

I sometimes daydream about having a 3D printer in my office for those times when I can't find a fork to eat my to-go salad. Perhaps that's a bit of a stretch, however, the recent improvements in 3D have allowed for printers that are more compact and less expensive, making them available to the average consumer with an interest in such things.

The comprehensive 3D-focused website ALL3DP reviews the top 10 3D printers as of January 2017. Prices range from $650 to $3500 and not surprisingly, at least five of the recommended 10 are available for purchase on Amazon.

The speed of 3D printers has drastically increased of late, allowing for easy and rapid proto-typing, which in turn enables a quicker turnaround time from idea to manufacture. Once the proto-type is to spec and approved, mass production can begin. Additionally, small run production is surely an option with the newer, faster, cheaper, more efficient printers and the myriad media used for printing. At least on paper, "less waste" should be a high level side effect of incorporating 3D technology into manufacturing processes where applicable.

All3DP has identified 30 types of 3D printing filaments with varied tensile strength, resilience, translucence, smooth finish, wood finish, nylon, metal and more, and still others are under development. If you're wondering about the possibilities for 3D-printed items, they also provide a list of useful doo-dads like a shower head, sliding door, bolt, earbud holders and more. Because 3D is highly customizable, small surgical tools and implantable prosthetics for cranial and dental surgery, as well as bio-printing of tissues and organs to eliminate the concerns of finding organ donors for patients in need are already in progress.

The future of 3D printing is now - how would you like to see this amazing technology applied?

Liberty Intercept Blog

3D Printing - The Future is Now

Posted by Elaine Spitz on Mar 16, 2017 10:17:36 AM

more efficient 3D printers. 3D printing had its advent in 1983, with a printer invented by Chuck Hull called a stereolithographer (SL or SLA), that used UV-curable liquids as its media.

3D printing, also known as additive manufacturing (AM), according to Wikipedia, refers to "processes used to synthesize a three-dimensional object, in which successive layers of material are formed under computer control to create an object."

Simply put, 3D printing starts with a digital design, which is then realized by the printer by adding layers of material, resulting in a three-dimensional physical object.

I sometimes daydream about having a 3D printer in my office for those times when I can't find a fork to eat my to-go salad. Perhaps that's a bit of a stretch, however, the recent improvements in 3D have allowed for printers that are more compact and less expensive, making them available to the average consumer with an interest in such things.

The comprehensive 3D-focused website ALL3DP reviews the top 10 3D printers as of January 2017. Prices range from $650 to $3500 and not surprisingly, at least five of the recommended 10 are available for purchase on Amazon.

The speed of 3D printers has drastically increased of late, allowing for easy and rapid proto-typing, which in turn enables a quicker turnaround time from idea to manufacture. Once the proto-type is to spec and approved, mass production can begin. Additionally, small run production is surely an option with the newer, faster, cheaper, more efficient printers and the myriad media used for printing. At least on paper, "less waste" should be a high level side effect of incorporating 3D technology into manufacturing processes where applicable.

All3DP has identified 30 types of 3D printing filaments with varied tensile strength, resilience, translucence, smooth finish, wood finish, nylon, metal and more, and still others are under development. If you're wondering about the possibilities for 3D-printed items, they also provide a list of useful doo-dads like a shower head, sliding door, bolt, earbud holders and more. Because 3D is highly customizable, small surgical tools and implantable prosthetics for cranial and dental surgery, as well as bio-printing of tissues and organs to eliminate the concerns of finding organ donors for patients in need are already in progress.

The future of 3D printing is now - how would you like to see this amazing technology applied?

Topics: 3D Printing

Popular Posts

Aluminum Does Rust, Just Not the Way You're Thinking

Corrosion via Corrugate

A Look at Packaging Costs

Leave a Comment