I had the opportunity to hear the vice president of a major computer company speak about reliability and the tactics they use to achieve increased product reliability. Because human nature strives to keep things the same and views change as uncomfortable, he emphasized that the change process was long and arduous. This VP was brought in like the new sheriff arriving in Dodge City. It was apparent he had complete executive support to change this company’s operation and design systems; in doing so he would enact a change in its culture. It worked famously. Their return has been extraordinary; they achieved tremendous increases in product reliability which led to lowered cost of goods on every level of the corporation and a stronger reputation amongst their customers.

I had the opportunity to hear the vice president of a major computer company speak about reliability and the tactics they use to achieve increased product reliability. Because human nature strives to keep things the same and views change as uncomfortable, he emphasized that the change process was long and arduous. This VP was brought in like the new sheriff arriving in Dodge City. It was apparent he had complete executive support to change this company’s operation and design systems; in doing so he would enact a change in its culture. It worked famously. Their return has been extraordinary; they achieved tremendous increases in product reliability which led to lowered cost of goods on every level of the corporation and a stronger reputation amongst their customers.

I have heard it numerous times: “We don’t have quality problems in our company; we don’t have defects.” Perhaps so, or maybe it’s just a complex subject to address.

The problems are there. On the commercial side of computer making, a 2009 study conducted by SQUARETRADE showed that 1/3 of laptop computers sold will fail within three years; wow, I’m hugging my four year old laptop daily! This study goes into detail about the types of failures and which laptop computers are statistically more reliable.

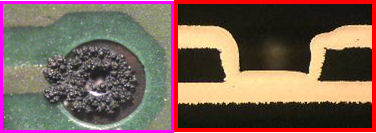

At Liberty Packaging, increased product reliability is a benefit we can provide with our Intercept corrosion and ESD protective packaging. With Intercept packaging, we can help solve product defects, increasing reliability in the process.

Based on case studies of current Intercept users, the effort to change is worth making. A recent Bell Labs white paper states that Alcatel-Lucent increased product reliability by 1.5% by switching from standard protective packaging bags to Static Intercept bags. That improvement provided a huge carbon footprint savings to their operations.

What could Intercept Packaging do for your operation?

Intercept Technology Packaging products fit within a sustainability strategy because they are reusable, recyclable, do not contain or use volatile components (No VOCs, Not a VCI) and leave a smaller carbon footprint than most traditional protective packaging products.

Liberty Intercept Blog

Reliability vs. Product Defects

Posted by Joe Spitz on Jun 16, 2011 7:16:00 AM

I have heard it numerous times: “We don’t have quality problems in our company; we don’t have defects.” Perhaps so, or maybe it’s just a complex subject to address.

The problems are there. On the commercial side of computer making, a 2009 study conducted by SQUARETRADE showed that 1/3 of laptop computers sold will fail within three years; wow, I’m hugging my four year old laptop daily! This study goes into detail about the types of failures and which laptop computers are statistically more reliable.

At Liberty Packaging, increased product reliability is a benefit we can provide with our Intercept corrosion and ESD protective packaging. With Intercept packaging, we can help solve product defects, increasing reliability in the process.

Based on case studies of current Intercept users, the effort to change is worth making. A recent Bell Labs white paper states that Alcatel-Lucent increased product reliability by 1.5% by switching from standard protective packaging bags to Static Intercept bags. That improvement provided a huge carbon footprint savings to their operations.

What could Intercept Packaging do for your operation?

Topics: American manufacturing, reliability, quality, cost of goods reduction

Related Posts

Contamination Testing

Packaging's Crucial Role vs FOD

Customer Service with a Smile

Leave a Comment