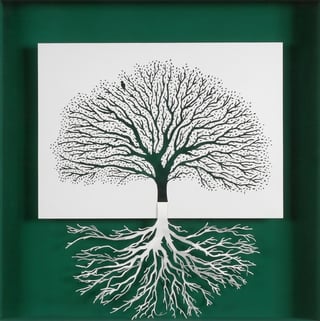

From Wikipedia: “In Chinese philosophy, yin and yang (陰陽 yīnyáng, lit. "dark-bright", "negative-positive") describe how seemingly opposite or contrary forces may actually be complementary, interconnected, and interdependent in the natural world, and how they may give rise to each other as they interrelate to one another.” The intent of retail packaging versus that of packaging for industrial use may seem unrelated at first glance, but I maintain they are most certainly connected.

I’ve been attracted to logos and packaging design for years, dating back to when I began working in the promotional products industry. Promo products are fun and often useful - you know what I mean: all the sticky notes, pens, pocket-sized measuring tapes, fleece vests, beer koozies, imprinted gift boxes, and other swag you see at trade shows, banks, and etc. You don’t have to look hard to notice that swag is everywhere. The logo is front and center, and the giveaway on which the logo is imprinted is ideally handy enough to stay in use for a period of time, keeping the brand, and thus the company, top of mind for a while. The promo products industry, like much of retail packaging, is about branding, but the smartest consumer-products manufacturers know that ease of use and product freshness are important to their customer.

Now, having been involved with industrial packaging for the last 20 years, I’ve been able to view packaging and branding from a different perspective, seemingly the opposite of retail. In pondering the differences, I began seeking the similarities of retail vs industrial packaging.

Retail packaging sometimes changes more often than the product being packaged, to keep up with design trends, and also as innovations in materials and machine technology evolve. Less waste, prolonged product freshness, ease-of-handling, and safe transport are in the top tier of goals for good packaging. In the competition for retail shelf space, of course, the final presentation must also offer the most eye-catching and pleasing look to the manufacturer’s desired audience. It’s all an effort to provide value to the intended user so they learn to trust the brand and continue to return as a customer. Great retail packaging can enable the customer to eliminate one more decision from their day, and that is of great consequence, especially in a world where we have so many (too many?) choices.

Industrial packaging is generally less colorful, less eye-catching, less sexy, however the factors that help keep the product stable, in usable condition (prolonged product freshness), and allow for reduced waste, ease-of-handling, and safe transport, remain equally vital. In fact, I maintain that industrial packaging materials may have increased importance, in that the products being protected are often significant pieces to a bigger puzzle. Consider the small metal geroters that will become part of the workings of a helicopter. It doesn't need to be pretty, but the packaging that keeps that geroter from rusting is key to ensuring the safety of that helicopter when it's in use.

The ideal situation when designing (or redesigning) any product, whether for retail or industrial use, is that the packaging materials are part of the consideration process from the beginning. Integrating all facets of the product and packaging design with priority for form, function, and freshness is simply better for the entire supply chain, as well as the end-user. In some instances, RFID or other means should be considered to thwart counterfeiting efforts in industries where that is a concern. High quality packaging materials that help food, electronics, pharmaceuticals, machinery, optics, and everything else that is farmed or manufactured maintain their usefulness for as long as possible, during shipment and storage, is of the utmost importance.

The differences between requirements for retail packaging vs industrial packaging are many, but there are similarities in philosophy in that both ideally include choices in materials and processes best suited to keeping the product fresh and ready to use when pressed into service at destination. Regardless of who is your customer, retail or industrial, the expectation should be that they can be satisfied with the product you've supplied, and feel it a worthwhile and safe investment. Indeed, a worthy goal for all producers, manufacturers, and makers.

What attributes do you think are most important when considering packaging design? Please tell us in the comments section below.

Liberty Intercept Blog

Retail vs Industrial Packaging: Yin and Yang

Posted by Elaine Spitz on Nov 28, 2017 4:18:53 PM

From Wikipedia: “In Chinese philosophy, yin and yang (陰陽 yīnyáng, lit. "dark-bright", "negative-positive") describe how seemingly opposite or contrary forces may actually be complementary, interconnected, and interdependent in the natural world, and how they may give rise to each other as they interrelate to one another.” The intent of retail packaging versus that of packaging for industrial use may seem unrelated at first glance, but I maintain they are most certainly connected.

I’ve been attracted to logos and packaging design for years, dating back to when I began working in the promotional products industry. Promo products are fun and often useful - you know what I mean: all the sticky notes, pens, pocket-sized measuring tapes, fleece vests, beer koozies, imprinted gift boxes, and other swag you see at trade shows, banks, and etc. You don’t have to look hard to notice that swag is everywhere. The logo is front and center, and the giveaway on which the logo is imprinted is ideally handy enough to stay in use for a period of time, keeping the brand, and thus the company, top of mind for a while. The promo products industry, like much of retail packaging, is about branding, but the smartest consumer-products manufacturers know that ease of use and product freshness are important to their customer.

Now, having been involved with industrial packaging for the last 20 years, I’ve been able to view packaging and branding from a different perspective, seemingly the opposite of retail. In pondering the differences, I began seeking the similarities of retail vs industrial packaging.

Retail packaging sometimes changes more often than the product being packaged, to keep up with design trends, and also as innovations in materials and machine technology evolve. Less waste, prolonged product freshness, ease-of-handling, and safe transport are in the top tier of goals for good packaging. In the competition for retail shelf space, of course, the final presentation must also offer the most eye-catching and pleasing look to the manufacturer’s desired audience. It’s all an effort to provide value to the intended user so they learn to trust the brand and continue to return as a customer. Great retail packaging can enable the customer to eliminate one more decision from their day, and that is of great consequence, especially in a world where we have so many (too many?) choices.

Industrial packaging is generally less colorful, less eye-catching, less sexy, however the factors that help keep the product stable, in usable condition (prolonged product freshness), and allow for reduced waste, ease-of-handling, and safe transport, remain equally vital. In fact, I maintain that industrial packaging materials may have increased importance, in that the products being protected are often significant pieces to a bigger puzzle. Consider the small metal geroters that will become part of the workings of a helicopter. It doesn't need to be pretty, but the packaging that keeps that geroter from rusting is key to ensuring the safety of that helicopter when it's in use.

The ideal situation when designing (or redesigning) any product, whether for retail or industrial use, is that the packaging materials are part of the consideration process from the beginning. Integrating all facets of the product and packaging design with priority for form, function, and freshness is simply better for the entire supply chain, as well as the end-user. In some instances, RFID or other means should be considered to thwart counterfeiting efforts in industries where that is a concern. High quality packaging materials that help food, electronics, pharmaceuticals, machinery, optics, and everything else that is farmed or manufactured maintain their usefulness for as long as possible, during shipment and storage, is of the utmost importance.

The differences between requirements for retail packaging vs industrial packaging are many, but there are similarities in philosophy in that both ideally include choices in materials and processes best suited to keeping the product fresh and ready to use when pressed into service at destination. Regardless of who is your customer, retail or industrial, the expectation should be that they can be satisfied with the product you've supplied, and feel it a worthwhile and safe investment. Indeed, a worthy goal for all producers, manufacturers, and makers.

What attributes do you think are most important when considering packaging design? Please tell us in the comments section below.

Topics: better packaging, reasons for packaging, quality

Related Posts

Contamination Testing

Packaging's Crucial Role vs FOD

Statue of Liberty Copper Patina = Corrosion

Leave a Comment