A look at how auto manufacturers saved money by switching to

Intercept Packaging

This presentation focuses on companies from the auto industry, but because Intercept is such a versatile material, companies from many different industries can save by switching to this advanced technology. INTERCEPT® particles are permanently bound to a polymer matrix and react with corrosive gases which are present in the atmosphere. Through this reaction, the inside of the package is neutralized of corrosive gases and permeating humidity is stripped of corrosive elements. Click here to learn more about how Intercept Technology works.

Intercept Packaging has many benefits

Companies who have switched to Intercept from an oil dip and VCI bag combo have seen as much as 1.8 million Euro in savings per year.

Here are a few real situations where companies got real savings by switching to Intercept

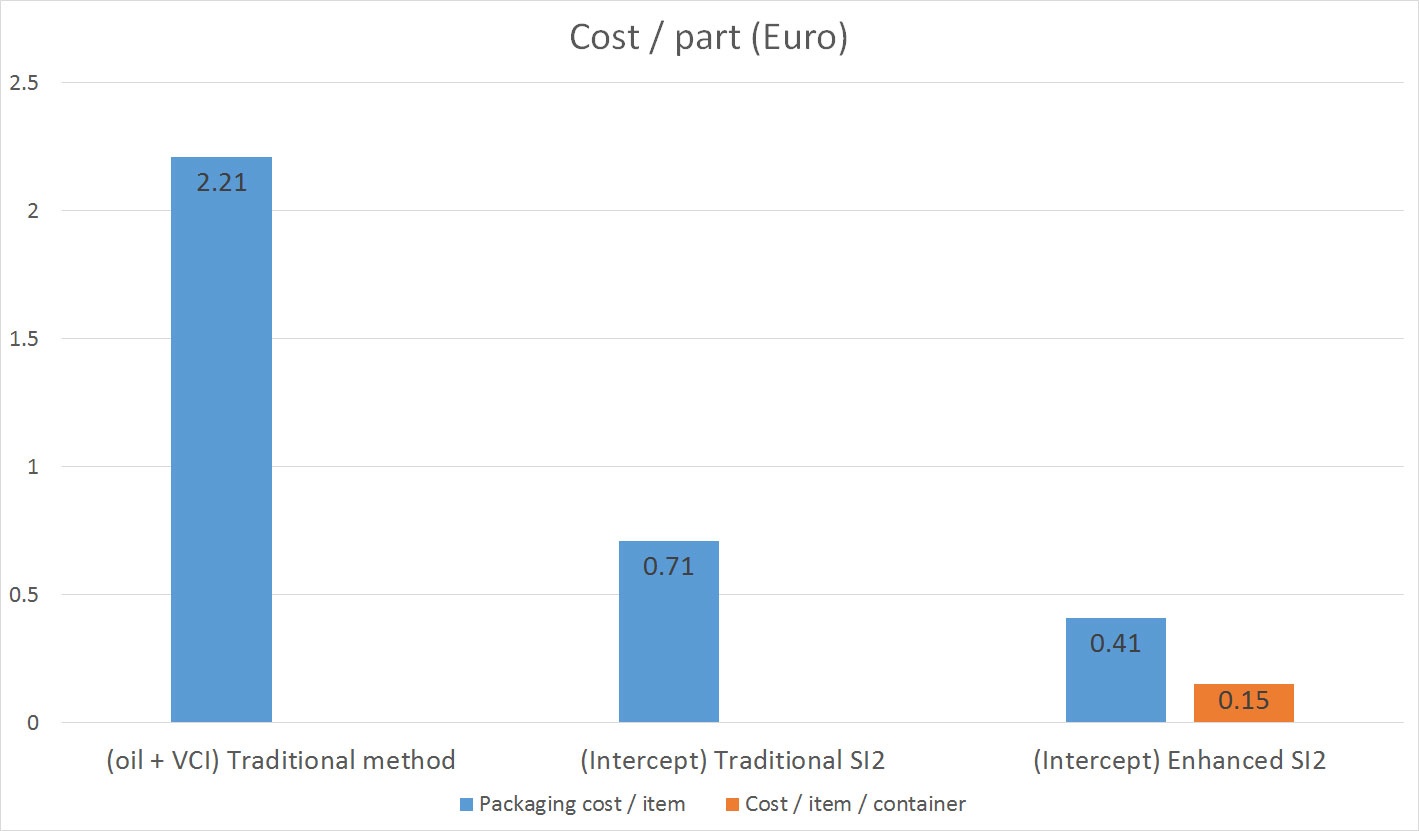

A company was shipping camshaft intakes in pallets of 150 parts with a packaging cost per part of 2.21 Euro. By switching to Intercept packaging, they were able to get rid of the price of the oiling and de-oiling bringing the packaging cost per part down to 0.71 Euro. They found additional savings with the switch because they were able to fit 340 parts to a pallet. With this higher load density the packaging cost per part came down to 0.41 Euro. The new pack also allowed more pallets to fit in a container creating another 0.26 Euro in savings.

That's a 93% savings in packaging cost

Other companies were rewarded with similar savings:

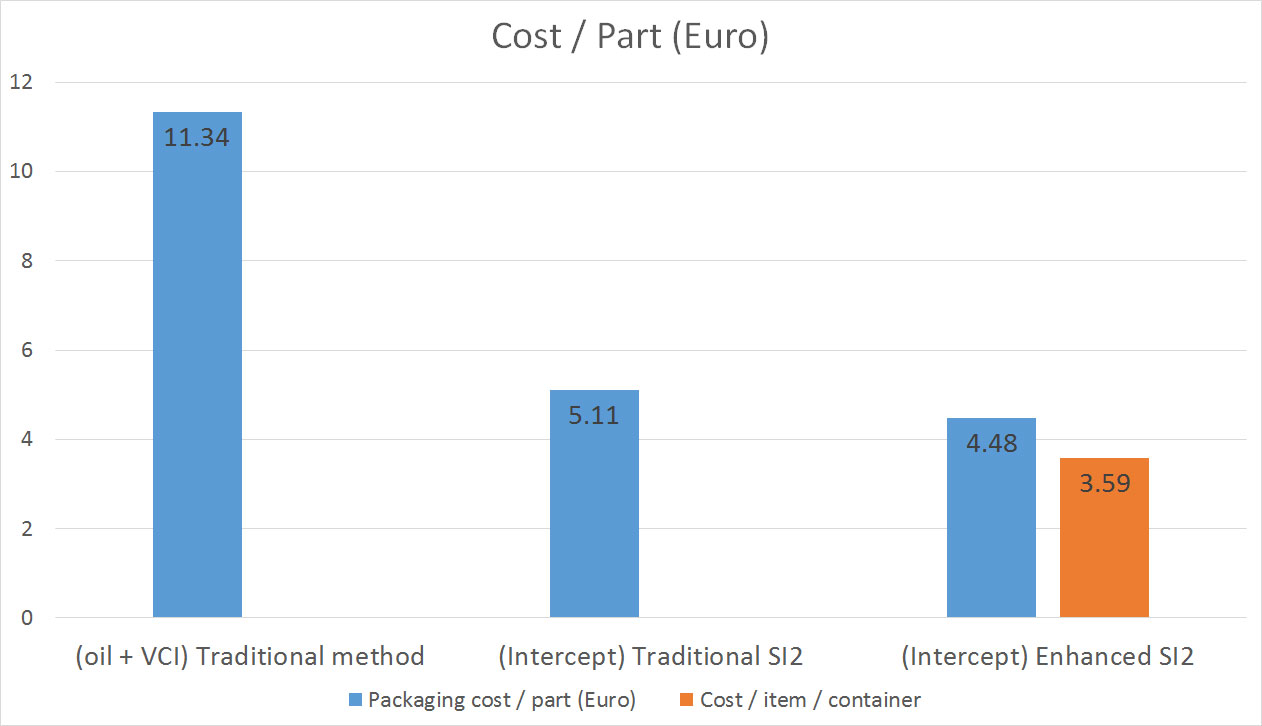

This company made the switch and saved 68% on their packaging

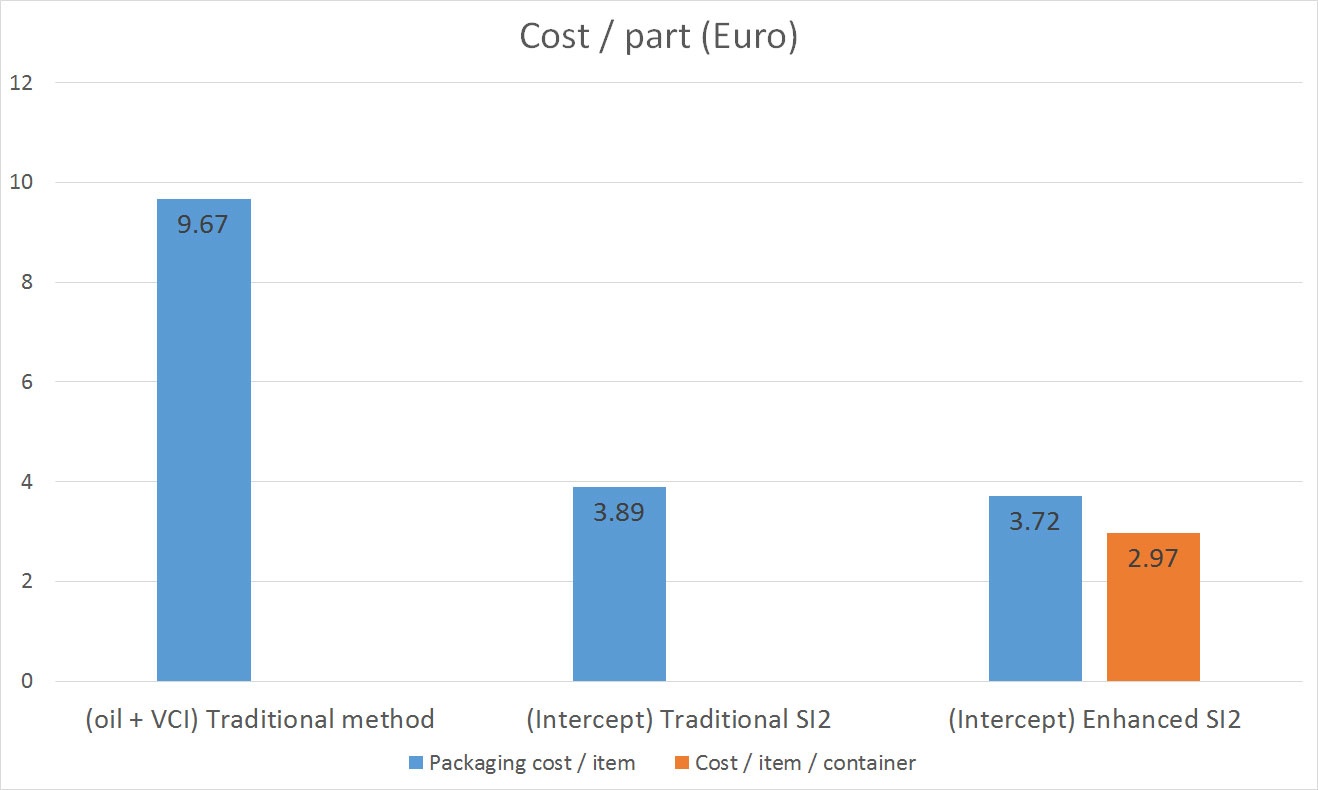

Here the switch to Intercept was worth 69% of their packaging cost

A final breakdown of the advantages of using Intercept

Your results may vary, but let's get started

Call

for a quote or